Perhaps you are searching for a Volvo PCV system diagram.

You may have been encountering problems with your Volvo, and now you want to address these. In fact, many people have experienced issues with their Volvo PCV system. Despite the upgrades made on this system, it appears that the issues continue to occur. What gives?

If you are dealing with an issue with your PCV system, this post may help you out. Keep reading to gain a better understanding of this system and what you can do.

Let’s get started.

Volvo PCV System Diagram, Facts, Issues

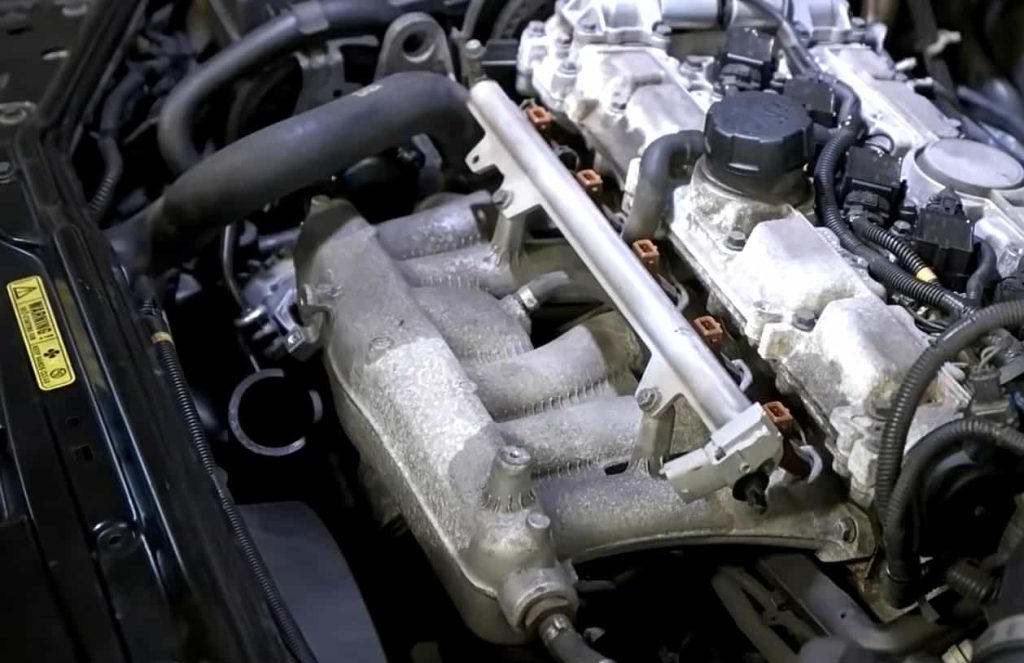

When you want to service your flame trap or crank case ventilation system properly, this involves replacing components of the system. This is quite a costly job, especially when it comes to the labor piece. It is necessary to have the intake manifold removed.

Ideally, you need to replace key components of your flame trap system every 100,000 or so – this depends on the oil quality you have, as well as the driving conditions and intervals of oil change sessions.

Over time, the fittings and the plastic tubing become very brittle. Additionally, there will be internal restrictions due to sludge and oil deposits in the tubing. Because of the restriction to the breather flow, this results in too much pressure in the crankcase. Then, this starts to force your oil past the seals.

If you continue to let this problem persist, the seal may eventually fail. Therefore, there may be a quick oil pressure loss, not to mention a serious engine failure.

PCV issues come in different forms. Basically, the PCV valve is made up of a PCV box and hoses. There is one positive ventilation called the road draft tube. This is primarily a tube that comes off the engine’s side and then faces under your car. Using a vacuum that your car creates, the tube extracts gas from your engine and expels them – and some oil – on the ground.

This pretty much explains the black strip found on the highway, which is the oil and gas that comes out of your PCV system.

Now, in the 1960s, engineers have started to incorporate vacuum in the vehicle’s intake system. This helps to draw gas right out of your crankcase. As a result, a positive crankcase ventilation is produced, and the gas is re-burned to minimize pollution. In fact, some studies were conducted to show that 50 percent of hydrocarbons emitted into the air came from crankcase ventilation.

Here is a volvo PCV system diagram that you may find to be helpful

Ever since then, Volvo has stopped using the PCV valve. Instead, they use an oil separator box including rubber hoses responsible for connecting the intake system to the crankcase. Moreover, your breather box is what separates oil mist from vapors. Therefore, oil is no longer re-burned.

However, the PCV system is susceptible to damage due to various factors including heat, chemicals underneath the hood, and environmental elements. Therefore, the system fails far too often. This is why it is a common complaint among Volvo owners.

If you only use your Volvo in short distance driving and less frequently, this prevents the engine from getting too warm, and oil does not heat cycle well. Hence, your vehicle is more prone to accumulate contaminants in the PCV system. And ultimately, the PCV parts tend to fail more often than not.

With that being said, there is no such thing as a mileage interval when it comes to a PCV maintenance. Shorter trips mean having to do maintenance more. On the other hand, there are those that encounter issues with their PCV system even if they do frequent trips.

But keep in mind that so long as there are no cracks in your hoses, the system remains intact, and there are no blockages, the PCV system should still perform well. However, more PCV issues may come along when there are cracks to the PCV box, rubber components, nylon parts, and in the hoses. So, you need to get these addressed sooner than later.

Now, if you need to work on your PCV system because of certain issues, you may first want to look for symptoms. The most common sign that there is damage to your PCV system is when the check engine light switches on. Therefore, you would need to get yourself a PCV kit and some handy tools ready to resolve this issue.

This is a task that you should be able to perform in your own garage, assuming you have the necessary tools and some basic skills. Many PCV kits include an oil separator box, intake manifold gasket, oil dipstick tube seal, breather hoses and hose clamps, and fuel injector seals.

While these may suffice in replacing your PCV system, there may be other parts that would require a replacement. These include O-rings, seals, and smaller gaskets. This is why it is very important to inspect the entire system for certain parts that need to be fixed and replaced when you work on your PCV system.

Read More: 6.6 Duramax Coolant Flow Diagram & Issues To Keep In Mind

Wrap Up

As we have mentioned, your PCV system may be prone to damage because of several factors such as usage, wear to relevant parts, and environmental factors. This is why it is good to conduct an inspection of parts that may possibly have been damaged. Then, you would need to replace these immediately to avoid compromising the performance and lifespan of your vehicle.

It may also help to have an expert check on the PCV system for failures and faults. There are instances when you may be completely unaware of the problem or how to deal with it. This is why it is always good to have a specialist to diagnose the issue and provide the right troubleshooting techniques possible.

We hope this has been helpful in addressing this concern regarding the Volvo PCV system.