Are you thinking of ways on how to reset crankshaft position sensor no start issue?

When you are having a problem with starting your vehicle, and you suspect it has something to do with your crankshaft position sensor, it can be a frustrating ordeal.

After all, the last thing you want to experience is having delays in your schedule for the day.

But if this is something that bothers you, and you want to know how to deal with this concern, you are at the right place. We are here to share with you some useful tips and guides on how you can reset your crankshaft position sensor correctly. Let’s get started.

Contents

How To Reset Crankshaft Position Sensor No Start

The crankshaft position sensor is a crucial component in the engine management system of modern vehicles. It provides vital information about the position and rotational speed of the crankshaft, enabling the engine control unit (ECU) to determine the precise timing for fuel injection and ignition.

However, a faulty or misaligned crankshaft position sensor can lead to a “no start” situation, where the engine fails to ignite. In such cases, resetting the sensor may help resolve the issue and get your vehicle up and running again. Let’s explore the steps involved in resetting the crankshaft position sensor.

1. Identify the Symptoms

Before attempting to reset the crankshaft position sensor, it is essential to ensure that the symptoms you are experiencing are indeed related to this component. A no start condition can be caused by various other factors, such as a dead battery, a faulty ignition switch, or a malfunctioning fuel pump. Therefore, it is important to diagnose the problem accurately before proceeding.

2. Disconnect the Battery

To reset the crankshaft position sensor, start by disconnecting the negative terminal of the battery. This will ensure that no power is supplied to the engine or the ECU during the reset process. It is crucial to disconnect the battery to prevent any potential damage to the electrical system or sensors during the reset.

3. Locate the Crankshaft Position Sensor

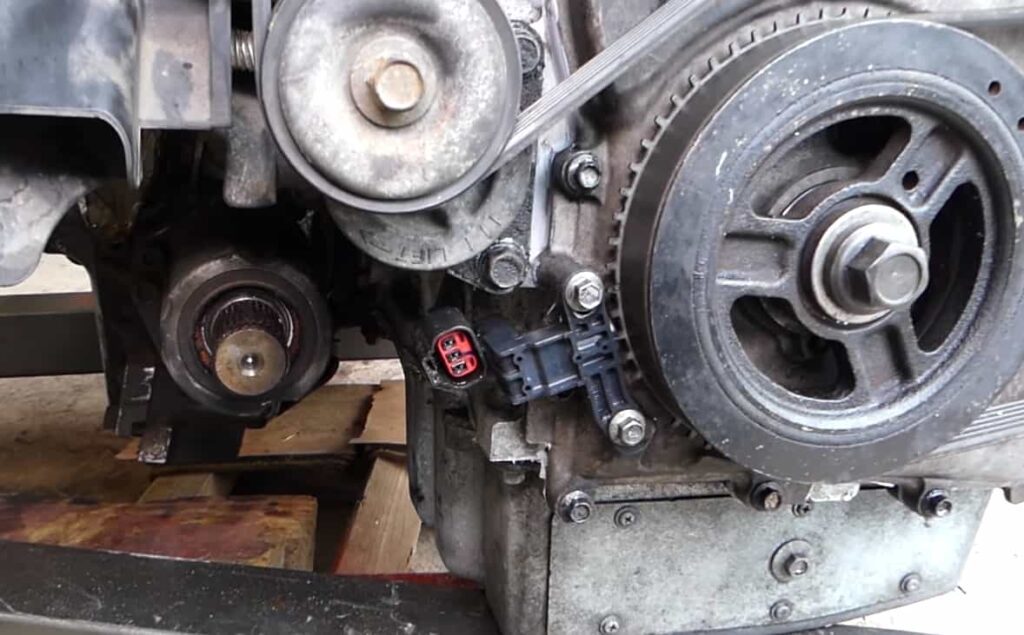

The exact location of the crankshaft position sensor may vary depending on the make and model of your vehicle. Generally, it is located near the crankshaft pulley or the flywheel. Consult the vehicle’s service manual or search online resources to determine the precise location for your particular vehicle.

4. Remove and Inspect the Sensor

Once you have located the crankshaft position sensor, carefully remove it from its mounting position. Inspect the sensor for any signs of damage, corrosion, or loose connections. Clean the sensor using an appropriate electrical cleaner if necessary, and ensure that the mounting area is free from debris.

5. Reset the Sensor

Resetting the crankshaft position sensor involves reinstalling it correctly and ensuring proper alignment. Follow these steps to reset the sensor effectively:

- Ensure that the sensor is properly aligned with the teeth on the crankshaft or flywheel. Improper alignment can result in inaccurate readings and a no start condition.

- Insert the sensor back into its mounting position and secure it firmly. Use the appropriate fasteners and torque specifications recommended by the manufacturer.

- Double-check all connections and wiring related to the sensor. Make sure they are properly connected and free from any damage or corrosion.

- Reconnect the negative terminal of the battery to restore power to the vehicle’s electrical system.

6. Test the Vehicle

After resetting the crankshaft position sensor, it is essential to test the vehicle to determine if the no start issue has been resolved. Turn the ignition key and listen for any abnormal sounds. If the engine starts smoothly and runs without any issues, the reset was successful. However, if the no start problem persists, it is advisable to consult a professional mechanic or an authorized service center for further diagnosis.

Reasons For Resetting Your Crankshaft Position Sensor

If you are wondering about the common reasons why you may need to reset the crankshaft position sensor, here are some instances that would require you to do a reset:

1. Sensor Malfunction

Over time, the crankshaft position sensor may develop faults or malfunctions. These issues can arise due to electrical problems, damage to the sensor, or wear and tear. When the sensor malfunctions, it may provide incorrect or erratic readings to the ECU, resulting in a no start or poor engine performance. Resetting the sensor can help recalibrate its settings and restore its proper functionality.

2. Misalignment

Another common reason to reset the crankshaft position sensor is misalignment. The sensor needs to be positioned accurately in relation to the teeth on the crankshaft or flywheel. If the sensor becomes misaligned, it may provide incorrect readings to the ECU, leading to timing issues and engine problems. Resetting the sensor involves reinstalling it correctly and ensuring proper alignment, which can help resolve any misalignment-related issues.

3. Sensor Cleaning

In some cases, a reset may be required after cleaning the crankshaft position sensor. The sensor can accumulate dirt, oil, or debris over time, which can interfere with its proper functioning. Cleaning the sensor with an appropriate electrical cleaner can help remove these contaminants. However, after cleaning, it is important to reset the sensor to ensure that it is recognized by the ECU and functioning optimally.

4. Electrical System Disruptions

Electrical system disruptions, such as a dead battery or a sudden power surge, can cause the ECU to lose its stored data and settings. When this occurs, the ECU may not recognize the crankshaft position sensor or may receive incorrect information from it. Resetting the sensor can help the ECU re-establish communication and synchronization with the sensor, allowing the engine to start and operate as intended.

5. Diagnostic Procedures

During the diagnostic process for engine-related issues, resetting the crankshaft position sensor is sometimes performed as a troubleshooting step. By resetting the sensor, technicians can eliminate any temporary glitches or errors that might be causing the problem. It provides a clean slate for the sensor to operate and allows the technicians to observe if the issue reoccurs, indicating a more significant problem that needs attention.

Read More: Expert Tips On Temporary Fix For Crankshaft Position Sensor

Final Thoughts

A malfunctioning or misaligned crankshaft position sensor can cause a no start situation, leaving you stranded and frustrated. However, by following the steps outlined in this article, you can attempt to reset the sensor and potentially resolve the issue.

It is important to note that while resetting the sensor may fix the problem in some cases, there could be underlying issues that require professional attention. If you are unsure about performing the reset procedure yourself or if the no start condition persists, it is recommended to seek assistance from a qualified automotive technician.