Some DT466 engine problems may come along at one point or another. And when these arise, it is best to know what to do about these, so you can determine how to fix them.

After all, these engine problems can be very much concerning. Plus, the last thing you want is to get in a lot of inconveniences with these.

So, without further ado, let’s go right ahead and talk about these DT466 engine issues. Find out what we can do to get these fixed and how to avoid them.

Common DT466 Engine Problems

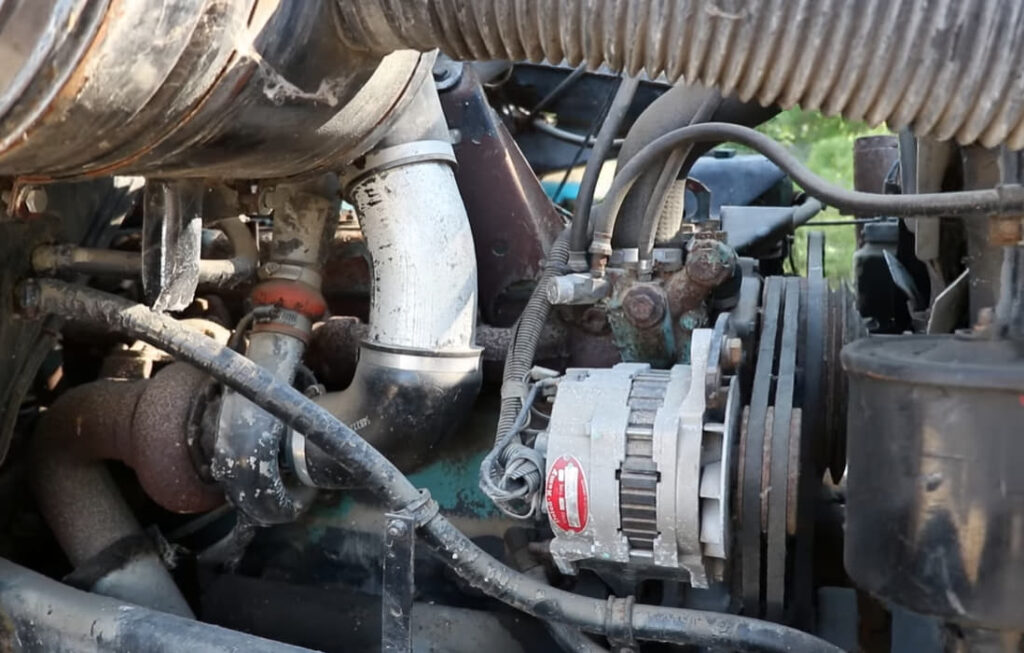

For the most part, the DT466 engine is regarded for use in medium heavy duty trucks and various other purposes. The strength and robust engine is regarded in many industries. It comes with forged steel rods that can handle more than 1000 horsepower and the crankshaft is over 150 pounds – and it is just as capable.

The head is quite secure with any variants as it uses 6 bolts for each cylinder. And lastly, there is a wet sleeve iron cylinder liner that offers easy servicing and great strength.

So many changes and improvements have transpired over the years for the DT466 engine. But overall, the purpose for these enhancements are to improve the emissions, performance, and fuel economy.

There is also the DT466E, which is basically to indicate the electronic control added in. What this means is that the engine is computer-controlled. There are advancements made, particularly the HEUI updates.

Now, let’s talk about the performance, the earlier models of the DT466 engine produce less power and are not at all impressive by modern standards. This is especially when in comparison with light-duty truck engines such as the Cummins and 6.7 PowerStroke that can generate over 1000 torque.

Yet, the DT466 may have a lower output but you can rely on it. The engine is more than any torque and power that were over-built. This is why it is still reliable for numerous applications.

It is important to note that the cylinder head needs to be addressed when aiming for a bigger power. But this does not occur until about 1000 up to 1200 horsepower. There are also the crankshaft and the forged steel rods that are capable of more than 1500 horsepower.

But overall, the DT466 engine is still a dependable engine in high performance tractors for obvious reasons. The structure is incredibly powerful. Although there are issues that come along such as with the emissions and electrical system.

The problem with the electrical system, however, is not very serious. Instead, these are small problems that arise, yet the details add to the complications in getting them fixed.

One example is when you use compressed air in pumping oil into your engine, starting problems may arise. Because air gets into the oil, this messes with your HEUI system. Hence, the engine may experience starting issues.

In the case of the DT466E that comes with more parts and more sensors, this causes more possible failure than with the DT466 engine.

Then, there is the problem with the injector return line. Although the DT466 is a reliable engine, the injector return line may incur some issues. These lines are constructed from rubber, and this makes them prone to issues such as leaking fuel that gets on the valve cover.

Thankfully, this is not a very serious issue. Over time, the rubber lines just dry out and form cracks. Some fuel may get onto your valve cover, but an easy fix for this problem is to replace the rubber hoses. Since the hoses are cheap to replace, you can definitely get these changed when problems begin to present themselves.

Read More: MBE 900 Engine Problems You Need To Know

Is The DT466 Engine Reliable?

When it comes to reliability and performance, we can honestly say that you can depend on the DT466. These are extremely well-made and reliable engines, and it is even possible for the engine to outlast the actual truck.

Because of their reputation of being reliable, DT466 engines are depended on for commercial purposes. Moreover, the mechanical design is simple and without any complications. This is, however, before emissions control devices and sensors were added into the latest design.

But with all things said and done, the engines are indeed reliable and sturdy. They are also easy enough to repair when problems arise over the years. The cylinder heads rods, wet sleeves, cranks, and blocks are robust and powerful. These parts can even handle over 1000 horsepower before upgrades or modifications would be required.

Because of the ultimate strength of the engine, it is regarded in tractor pulling industries and other heavy-duty work. So, if problems do arise, it is best to get them sorted out while still starting instead of waiting it out until things get worse. This way, you can prevent serious problems that can also be a more expensive fix.