Cummins ISX15 oil pressure problems arise at certain points throughout the lifespan of your vehicle.

This is why you need to be aware of some symptoms that come with it, so you can prevent serious damages to your engine and its components.

Always remember that driving your vehicle with a low oil pressure is a bad idea. This can result in a premature wear and tear of your engine parts. Moreover, engine failure may occur, which is a very expensive repair to deal with.

Thankfully, there are early signs you can take note of before this even happens. Your oil pressure sensor will let you know if the oil pressure falls below the normal range. This is why you need to have it rectified and addressed sooner than later.

Discover more about these oil pressure problems with the Cummins ISX15 and what you can do about them.

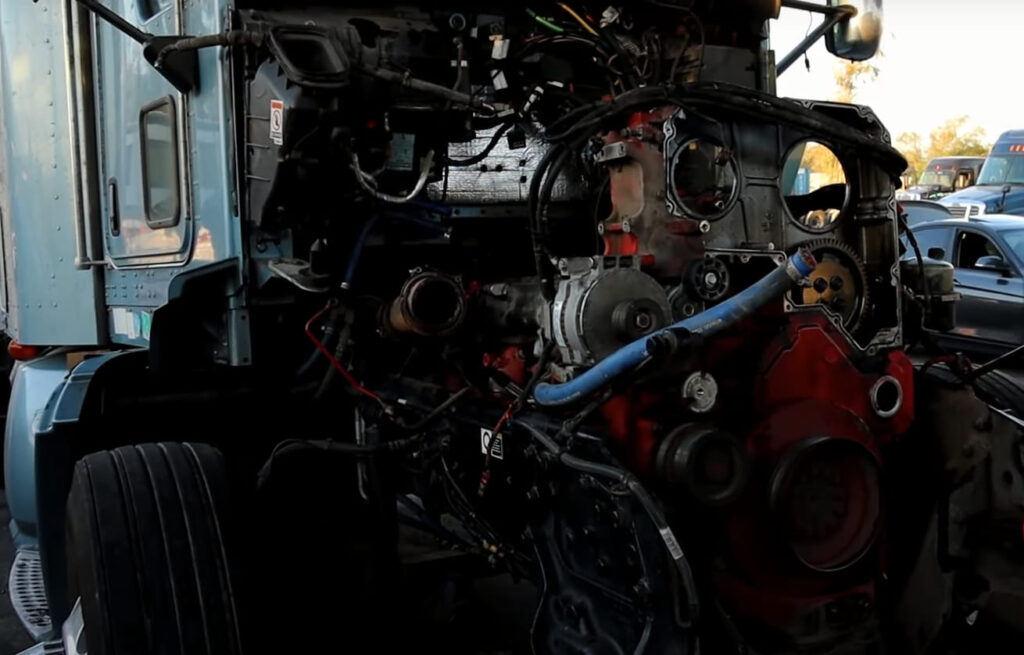

Cummins ISX15 Oil Pressure Problems

There are many reasons why oil pressure problems may arise, and some symptoms that will let you know of this issue before things get worse.

For the most part, skipping an oil change schedule for a long time can be a contributing factor to low oil pressure. An issue with your oil pressure sensor, as well as the wiring, can also result in this issue.

In most cases, the oil pump is unlikely to fail. However, this can still occur, which is why you need to pay close attention to its performance and condition. You may consider changing your oil and observing if the low oil pressure problem is fixed.

Most people will immediately assume that an oil pressure issue is a very critical problem. In fact, you may panic and think that it is a big issue to fix. But thankfully, many of the common causes of low oil pressure and the symptoms that come with them may only require a simple fix.

But before you begin with an inspection of your engine parts, be sure to keep all components clean and void of any contaminants. When there is debris or dirt that enters your engine, this can contribute to a premature wear and tear. Misalignment of some crucial parts or any blockage to these components may also happen, which can clog oil passageways.

This is why you should consider using an oil pressure gauge. It helps to identify if the issue occurs in the bottom or top end of your engine.

You should also make sure that all necessary fluids are kept in check when you inspect engine parts. Maintain all required fluids and be sure these are not contaminated to avoid issues with the engine.

With all that being said, let us take a look at the common causes of the Cummins ISX15 oil pressure problems.

1. Low engine oil level

The very first thing to observe is the oil level. This is the common culprit, and there simply is no adequate oil in your engine. So, your oil pump will not work well when there is insufficient oil since it cannot pump enough oil to your engine components. Thus, add more oil to your engine to easily solve this problem.

2. Contaminated engine oil

Another thing to check is the quality of your engine oil. When there are contaminants, the oil pressure appears to be low. Too much fluid in your oil will eventually result in higher oil levels in your crankcase. When you have a high oil level, this will point toward fluid leaks in your engine.

Among the common contaminants to watch out for include coolant, water, and diesel fuel. This is why your mechanic will have to check the origin of the fluid leak and conduct necessary repairs. Once the contamination source is discovered and addressed, the oil needs to be drained and topped up with a suitable oil as recommended by your manufacturer.

You may also have to change your oil filter before refilling the oil. In some cases, a low oil pressure level is caused by a clog in the oil filter.

3. Open engine oil bypass valves

If your engine oil bypass valves are open, this can also lead to a low engine oil pressure. It may get stuck in an open position because of debris in the oil. Any debris such as metal shavings or dirt from the inside can damage the interior hard parts such as the pistons, crankshaft, and camshaft.

You can avoid further problems by removing the oil bypass valve and taking the debris out. You may also want to remove each of the bypass valve bore. After cleaning the bypass valves, be sure to change the oil and clean your oil filter.

4. Faulty oil passages or oil lines

Any oil passage or oil line that is broken, disconnected, or open will cause a below normal engine oil pressure. This is why your engine builder must inspect the oil passage for wear and tear or debris. There are also instances when oil galleries may be misaligned such as the holes not lining up properly to ensure the right oil flow. Inspect if your oil lines are attached correctly and there is no damage in your line.

5. Restrictions in your oil suction tube

Your oil suction tube comes with an inlet screen that can be damaged or clogged. When there is a restriction, this may lead to a cavitation and reduced engine oil pressure. So, you need to inspect your inlet screen on your oil pickup tube. Get rid of any obstruction that may be causing the oil flow to fail moving freely.

It is also possible that a low oil pressure may be due to a poorly positioned oil pickup tube. It may be drawing in air instead of oil, which is not a good thing. Check all the joints of your oil pickup tube and look for any signs of damage, misalignment, and cracks. You may need to remove your oil pan to access your oil pickup tube.

6. Oil pump issues

When there is a leak in your oil pump’s supply side, this can result in a back pressure or cavitation, as well as a low oil pressure. This is why you need to have your oil pump’s supply side checked and have any repairs done if need be.

Too much wear to your gears can also cause an issue with your oil pump. Any gears that are weak or worn out prevents it from having the right power to your engine.

Read More: Detroit Diesel Series 60 Ecm Problems – Everything You Should Know

Bottom Line

A low oil pressure issue can be serious, and it commonly happens with diesel engines. This is why you need to have the issue fixed before things get worse. Watch out for some signs of low oil pressure problems and have the root of the issue addressed sooner than later to prevent massive damage to other key components over time.