There are a number of Paccar MX 13 turbo actuator problems that may be troubling you.

And when one of these things happens, it can impact your productivity and bottom line. This is why it is important to understand what causes these issues and how to get them fixed.

We will talk about the common actuator problems with the Paccar MX 13, as well as possible fixes you need to know.

Contents

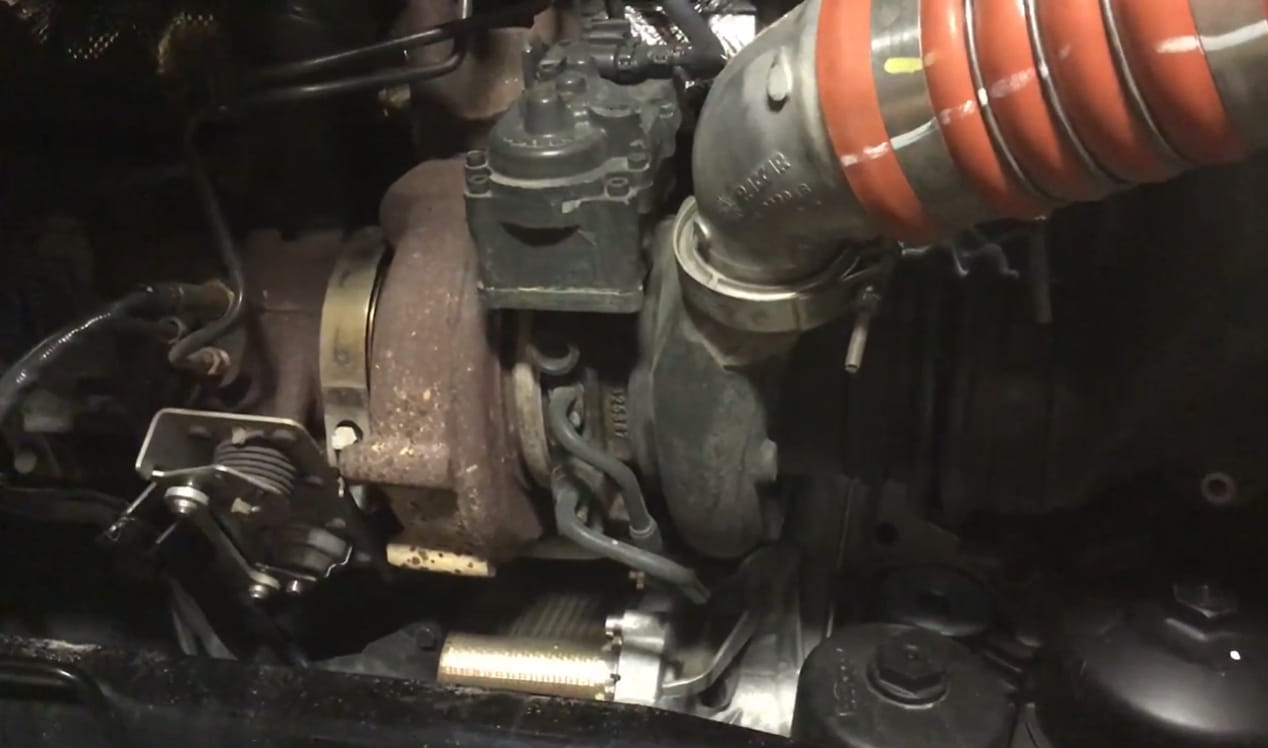

Paccar MX 13 Turbo Actuator Problems

A failed actuator can be due to a number of things. Here are just some of signs that your actuator is having some problems:

- Complete power loss

- Intermittent low pressure

- Overboost

- Low boost

- Turbocharger noise

- Flashing engine management light

- Fault codes

- ECU error symptoms control

There are also other signs that may arise but these are the most common ones that you can observe. Now, let’s proceed to the different actuator problems.

Turbo Actuator Problems

The following are problems that your turbo actuator may undergo, and we’ll explain them more into detail below.

1. Gearbox Failure

This is an issue caused by carbon build up. Thus, the motor burns out and causes the plastic worm gears to fail. When there is a low boost or your vehicle goes into limp mode, it could mean a failure in the gearbox.

Furthermore, the DPF may be blocked, or there may be soot or carbon buildup in the turbocharger. As a result, there’s further stress that can wear out and completely damage the components in the actuator such as the worm gear and motor gear.

2. Water Ingress

Your actuator is prone to water ingress because of the turbo’s position in the engine compartment. When this happens, there is a likelihood that your actuator can get contaminated or corrode. This will give incorrect signals while leading to its eventful damage.

3. Board Connectors

When the wire connectors expand and contract, further breakage and failure of the actuator may arise. It is difficult to detect this problem at its early stage, and the only way to know is the overheating of the actuator.

4. Damage Due To A Foreign Object

Next up, there may be damage to the actuator due to a foreign object found in the engine compartment. When this happens, you need to check the extent and nature of the damage to know the next step you need to take. Sometimes a simple repair is all that is needed but in some cases, it may require a full replacement.

5. Engine Vibration

When you notice a constant vibration in your vehicle, this will hasten the wear to the actuator. Over time, this component will fail.

Repair Work For Actuators

Actuators are complex components that will need a professional’s expertise for repair work. Moreover, depending on how serious the damage is, it may be essential to replace the unit completely as the best solution to the problem.

When you experience an issue with the turbocharger, you need to make sure that the rest of the components are still in perfect working condition and are maintained properly. Turbochargers are basically precision machines. They also come with a rotor system, which is capable of spinning for a maximum of 200,000 RPMs, varying on the turbo’s size.

But when things go downhill, these machines also become prone to damage rather quickly. Yet overall, turbos should be able to operate well during the engine’s lifespan.

Technicians are often tempted to go straight for the turbocharger. But at the same time, you need to understand the actual cause of failure by identifying and then addressing the root cause.

All clamps, water lines, pipework and aftertreatment systems need to be inspected when you check an engine. You also need to look at electrical connections and make sure there are no damages to these. Make sure the connections are tight as you don’t want to leak air or coolant, exhaust gas, or oil.

Read More: Freightliner Cranks But Wont Start? Reasons & Fixes You Should Know!

Final Thoughts

Misdiagnosis is often the reason behind the problem getting worse. If you encounter an issue in the systems and there is no power to the engine, you may end up pulling the turbo then changing it. But the ironic thing is that you may not be able to solve the problem, which is why proper diagnosis is very important.

Inspect it thoroughly and be sure that the issue is not in the actuator. Some technicians are quick to replace the actuator only to discover that it hardly ever solves the problem.

Because turbochargers are expected to last the life of the engine, inspecting the inside of the turbocharger reveals damage as well as clues to what could be causing it. So, you will need to inspect the rotor first and other components to make sure it’s not a worn out bearing or other issues similar to such.

Lastly, apply proper care techniques to the turbocharger. Make sure it gets enough oil to prevent it from burning out. All aftertreatment components also need proper maintenance as these parts impact the lifespan of the turbo.

Factory-recommended OEM oil is also preferable. Never miss the prescribed intervals for changing the oil, air, and fuel filters. By doing all of these, you can ensure the lifespan and performance of your turbocharger and actuator to eliminate unplanned downtimes and unexpected expenses coming your way.

Source:

https://www.thetruckersreport.com/truckingindustryforum/threads/paccar-mx13-losing-boost.1573107/