You may have been looking to find out about the cylinder head resurfacing cost and what to expect about it.

As you know, your vehicle’s engine pistons move so quickly inside the cylinders, which is why over time, this friction can lead to wear and tear to these components. When this happens, your engine fails.

But all hope is not lost. With a periodic resurfacing of the cylinder head, you can prevent this catastrophic situation from happening – while at the same time making sure that the engine is at its best performance.

It all comes down to knowing the cost involved, so you can go ahead with this procedure. This is what we will talk about today, so let’s get started.

Contents

Cylinder Head Resurfacing Cost

The typical ballpark for cylinder head resurfacing cost is about $500. This is the average price for many engine builds. However, it can go up to $700 in some cases.

Generally, resurfacing cylinder heads is much more cost-effective than replacing the entire cylinders. This also provides good maintenance that these components need over the course of their lifespan.

However, do take note that when the engine misfires, you can’t do a whole lot to save on expenses. This is why you need to ensure proper maintenance to also keep the expenses low when the time comes for it to be resurfaced.

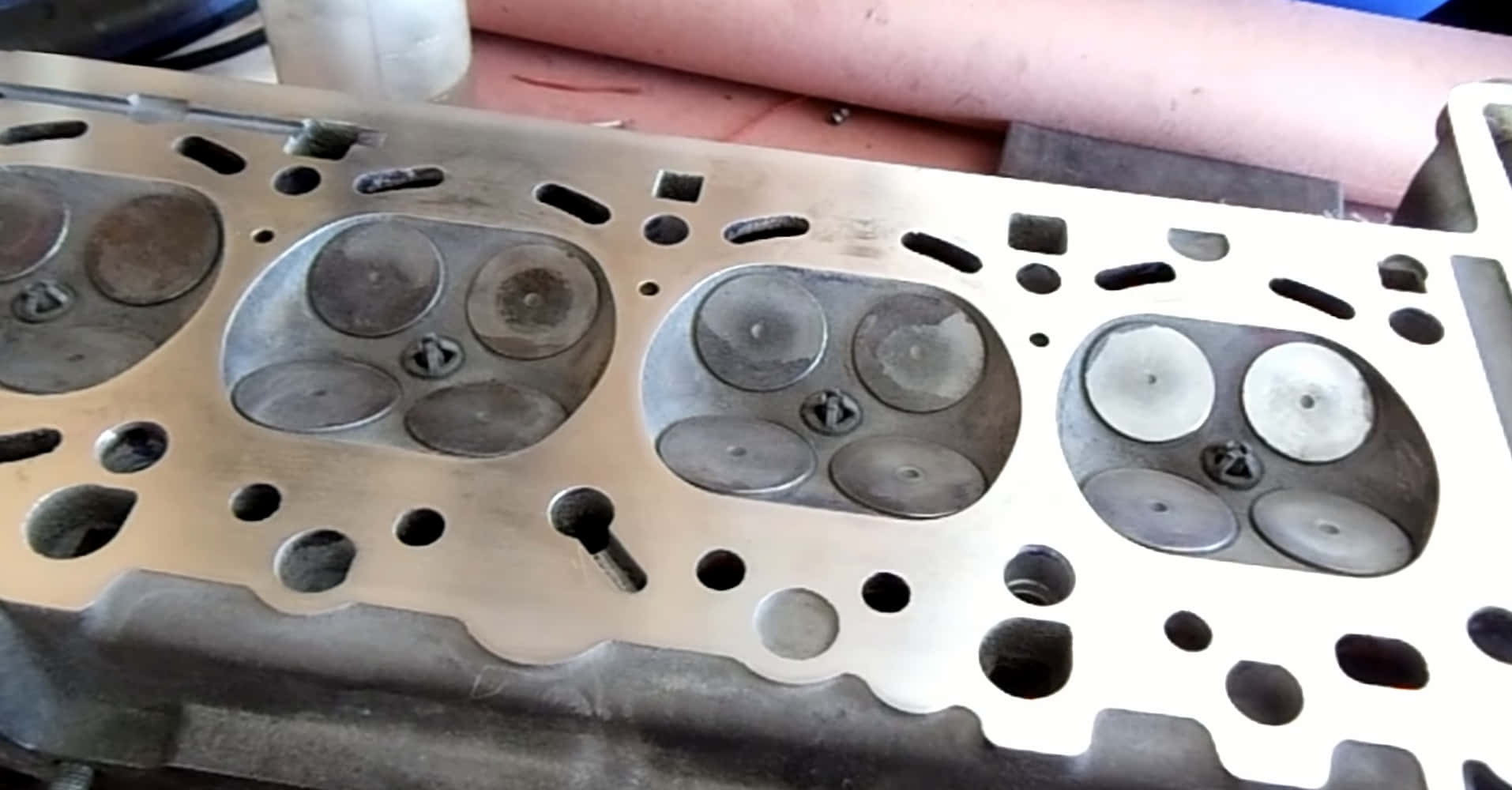

These heads form the upper portion of the engine. They also seal your combustion chambers, so the engine can burn more fuel required for power.

Over time, the heads wear down or crack. You may also notice some symptoms reminiscent of a blown head gasket or cracked block.

In most cases, people decide to purchase a brand new cylinder head. Yet, this is an expensive route and not always a necessity unless in extreme conditions. Thankfully, advanced technologies enable the rebuilding or resurfacing of worn out cylinder heads.

By resurfacing this component, this improves and even restores the finish of the blocks and heads. Since there are no new components needed, a typical resurfacing job should be a cheap task to do. It is usually at around $60 to as much as $80 on a per hour basis, which covers the labor cost.

The entire process is straightforward but can take a bit of time. This is because the heads must be skimmed and resurfaced, so expect to pay about $400 or so, depending on how many cylinders your vehicle has.

It is also worth noting that shops charge different prices depending on the engine’s material construction. The common materials used are cast iron, steel, and aluminum.

As for the typical price ranges, these are:

- $400 – $500 – 4-cylinder

- $500 – $600 – 6-cylinder

- $600 – $700 – 8-cylinder

Cylinder Head Resurfacing – What To Expect

Cylinder head resurfacing can easily be a DIY project if your vehicle uses cylinder heads made of aluminum. In fact, you may even have the right tools needed to do it.

But do take caution when you do it yourself – any mistake will easily damage your vehicle. This is why going to a professional for resurfacing cylinder heads makes so much more sense when restoring your car’s performance.

You will also need a professional’s expertise if you require special tools for resurfacing such as cast iron and mill steel. In addition, you may need a pro to get this job done for you when you want to stop a head gasket leak, clean up welds, align aftermarket intake manifolds, and restore flatness or increase compression ratio.

The process of resurfacing cylinder heads all begins with the proper milling machine, as this is what’s needed to achieve the optimal smoothness. This is why a milling tool equipped with a specific table feed speed and rate is important. Then, you can slow down or speed up the cutting head, helping you to achieve an ideal smooth finish.

PCD bits or carbide for aluminum cylinders or CBN for heads made of cast iron. When milled to the desired specifications, it is also important to clean and polish the finished head. This way, you can remove excess grease, oil, milling residue, and dirt since these contaminants speed up the wearing process that will give way to early signs of engine failure.

Additional Points To Consider

When you mill the head down, this offers better control over resurfacing since you can adjust the process depending on your vehicle specifications and equipment.

The only caveat to this is that it often leaves the surface dirty and rough. You can remove this residue through thermal or chemical cleaning, yet there are other techniques performed by shops to minimize equipment and labor costs.

This includes hand sanding, which is a typical alternative method to other laborious cleaning. Others implement belt sanding, which is a more conventional way of resurfacing cylinders. The only downside is that it does not offer as much precision as milling or grinding.

How Can You Tell Your Cylinder Heads Need Resurfacing

Wear and tear symptoms are the typical signs that you need to have your cylinder heads resurfaced. Because of an engine overheating, the cylinder head may crack. It is also the case with air trapped in your cooling system since the coolant can boil and cause damage to the heads.

Other issues that are detrimental to the cylinder heads are coolant leak, failed thermostat, bad water pump, loose cylinder head bolts, poor quality coolant or oil, and poor maintenance.

So, when you notice that there is oil or coolant leaking, or perhaps your engine is misfiring and not performing as normal, it is best to have your cylinder heads inspected by a professional to remedy the situation.

Read More: How To Protect Spark Plug Wires From Headers

Conclusion

Cylinder heads wear down over time because of a number of factors such as overheating of the engine, failed thermostat or water pump, poor quality oil used, and so on. When you observe signs of an oil leak, coolant leak, or engine smoke and misfiring, it is best to check your cylinder heads to see if there is damage that needs to be fixed.

The cost of resurfacing the heads is cheaper than buying new ones, so it is best to catch the problem while it’s still early to avoid more expensive repairs.